- Multiple-Beam X-ray scanners

- Baggage Scanner Manufacturing Companies

- Watch Airport CT Scanner Systems

- FACTS ABOUT BODY SCANNER

- Computed Tomography for Airport Security

- Combined Test Piece

- Common Baggage X-Ray ABBREVIATIONS

- X-Ray Baggage Inspection system technical specification

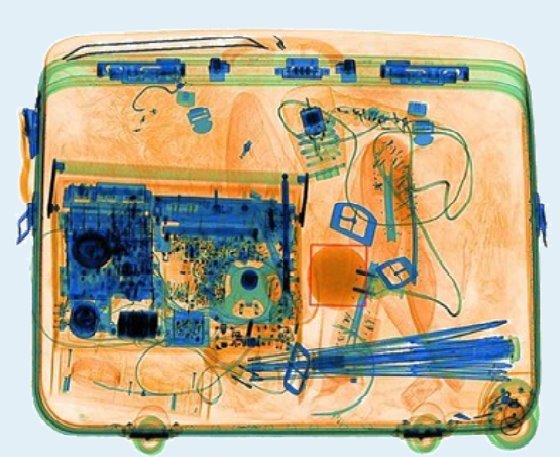

- CT image of a Bag

- Film Safe

- Radiation Levels

- Explosive Sniffing Dogs

- Explosive Trace Detection Machines

- Automated X-ray Machines

- EDS Machines

- All About X-RAY DETECTOR

- BCAS INDIA WEBSITE

- XBIS NEWS

Classification of XBIS based on the performance to Detect LEDS

Type A: the LEDS screens individual

containers and requires containers to be opened for sampling. LAG containers must

be removed from cabin baggage.

Type B: the LEDS screens individual

containers with no requirement for containers to be opened (original seal remains

intact). LAG containers must be removed from cabin baggage.

Type C: the LEDS screens multiple

containers with no requirement for containers to be opened (original seal remains

intact). LAG containers must be removed from cabin baggage.

Type D: the LEDS screens LAG containers

with no requirement for containers to be opened (original seal remains intact).

LAG containers do not need to be removed from cabin baggage.

Type D+: the LEDS is additionally capable

to screen LAG containers with complex electronics (e.g., laptops) present in

cabin baggage.

Computed Tomography for Airport Security

Watch Computed Tomography (CT) for Airport Security

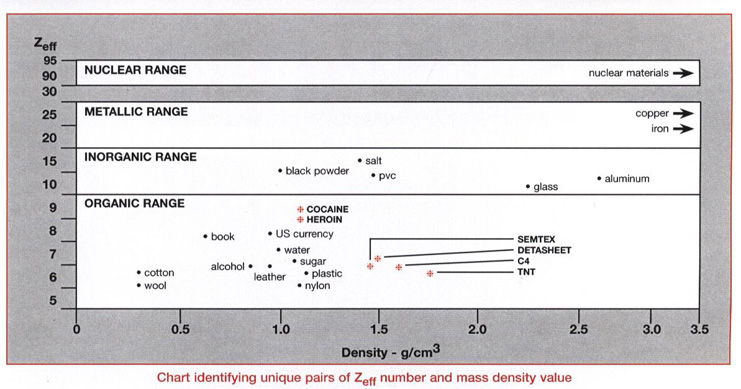

In Computed tomography (CT) system two-dimensional x-ray

images through an object are taken and added together to produce three-dimensional

image. The effective atomic number is calculated and materials with the same Z

number as explosives can be identified

Combined Test Piece.

The STP or CTP is used to ensure that the performance requirements for X-ray machines set out are met and maintained.Some times it is called Combined Test Piece (CTP) .The STP contains samples of organic and inorganic material, materials for resolution and penetration tests.

SINGLE WIRE RESOLUTION (TEST No.1)

SINGLE WIRE RESOLUTION (TEST No.1)

A set of un-insulated tinned copper

wires of size 26, 30, 35, 38, 40 and 42 SWG or corresponding AWG wires are placed on Perspex sheet. The

wires are laid out in 'S" shaped curves.

The wires are placed behind varying thickness

of aluminium. A quarter of the length of each wire is uncovered whilst the

remaining 3 quarters are covered by 3 wedges of aluminium, corresponding to

4.8mm (3/16"), 7.9mm (5/16") and 11.1mm (7/16") thickness. The minimum requirement

is to display 40 SWG wire not covered by step wedge for most of the machines. Metallic marker should be provided using

high-density material, so that SWG numbers in the Display are clearly visible.

USEFUL

PENETRATION (TEST No.2)

Defines what level of details can be seen behind a thickness

of known material. The requirement of this test is that the 26 SWG wire is seen

under step wedge of 5/16 thickness of Aluminium.

MULTI ENERGY X-RAY (TEST No. 3)

With multi-energy X-Ray, it should be possible to distinguish

between materials of different average atomic number. The use of sugar and salt

samples encapsulated on the test piece of CTP will check the material

discrimination facility. A different color of sugar and salt on display indicate that the sugar/salt samples are

shown in different color.

SIMPLE PENETRATION

(TEST No. 4)

This test defines what thickness of steel the machine should

be able to penetrate. The steel step wedge on the CTP has steps of 2 mm from 20

mm to 40 mm with a lead strip, 1.5mm in thickness to check that the machine is

above or below the requirement. The requirement will be different for different

KV machines.

SPATIAL RESOLUTION

(TEST No. 5)

This test defines the ability of the

system to distinguish and display objects which are close together. The CTP has

copper plate with three sets of gratings (1.0mm, 1.5mm and

2.0mm). Each set consists of a horizontal group and a vertical

group. The requirement is that a vertical and horizontal grating can be seen.

THIN METAL IMAGING

(TEST No. 6)

This is to test the machine‘s ability

to image thin metal. This involves a three thin squares of steel of 0.15mm,

0.10mm and 0.05mm thickness placed in row and the requirement is to image steel

strip of 0.1 mm thickness.

THIN ORGANIC IMAGING

(TEST No. 7)

This is to test the machine‘s capability for thin organic

imaging. The test object incorporates plastic of various thicknesses and the

requirement is to image plastic of 1 mm thickness.

IQI SENSITIVITY (TEST

No. 8)

This is to determine the image quality indicator (IQI) sensitivity of the X-ray system. The requirement is to demonstrate 2% IQI sensitivity.

The CTP must be placed with its longest

dimension parallel to the direction of belt.

The CTP should be

placed in the best position for optimum performance.The optimum position of the STP on the belt depends on the x-ray source and detector arrangements, with the aim being to obtain the best result possible.

Common Baggage X-Ray ABBREVIATIONS

ACSTL: Air Cargo Screening Technology List

ASAC Aviation Security Advisory Committee

ASTM:- American Society for Testing and Materials

AWG:- American Wire Gauge

ACBX:Advanced cabin baggage x-ray

BCAS (India):- BUREAU OF CIVIL AVIATION SECURITY

CBRN:- Chemical, biological, radiological and nuclear

CC:- Crystal Clear

CE:- Conformité Européene" which literally means "European Conformity".

CEP: Common Evaluation Process (for Security Equipment)

DGCA:- Directorate General of Civil Aviation

DFMD:- Door Frame Metal Detector

EPX:- Enhanced Performance X-ray

ETD Explosive Trace Detection

ECAC - European Civil Aviation Conference

HBS:- Hold Baggage Screening

HHMD:- Hand Held Metal Detector

HI-SPOT:- Online local area image enhancement

IM:- Inorganic Material

IMS:- Image Management System

LEDS:liquid explosive detection systems

LAGs:Liquids, Aerosols and Gels

NDS:- Network Display Station

NMS:- Network Management System

OM:- Organic Material

OTP-Operator Training Program

OTS-Link:- Image download & conversion

TIP:- Threat Image Projection

TSA:-Transportation Security Administration

SEN:- SUPER ENHANCEMENT

STP :-Standard Test Piece

X-ACT:- Advanced Contents Tracking

XBIS:- X-ray Baggage Inspection System

ASAC Aviation Security Advisory Committee

ASTM:- American Society for Testing and Materials

AWG:- American Wire Gauge

ACBX:Advanced cabin baggage x-ray

BCAS (India):- BUREAU OF CIVIL AVIATION SECURITY

CBRN:- Chemical, biological, radiological and nuclear

CBT-Computer

Based Operator Training

CE:- Conformité Européene" which literally means "European Conformity".

CEP: Common Evaluation Process (for Security Equipment)

CFR - Code of

Federal Regulations(US)

CONOPS:Concept of Operations

CTP:- Combined Test Piece CONOPS:Concept of Operations

DGCA:- Directorate General of Civil Aviation

DFMD:- Door Frame Metal Detector

DFT

-Department

for Transport(UK)

DTA- Density Threshold Alert

EDS:- Explosive Detection SystemsEPX:- Enhanced Performance X-ray

ETD Explosive Trace Detection

ECAC - European Civil Aviation Conference

HBS:- Hold Baggage Screening

HHMD:- Hand Held Metal Detector

HI-SPOT:- Online local area image enhancement

IM:- Inorganic Material

IMS:- Image Management System

LEDS:liquid explosive detection systems

LAGs:Liquids, Aerosols and Gels

NDS:- Network Display Station

NMS:- Network Management System

OM:- Organic Material

OTP-Operator Training Program

OTS-Link:- Image download & conversion

TIP:- Threat Image Projection

TSA:-Transportation Security Administration

SEN:- SUPER ENHANCEMENT

STP :-Standard Test Piece

STAC

-Service technique de l'aviation civile(Civil aviation France)

SWG:- Standard Wire GaugeX-ACT:- Advanced Contents Tracking

XBIS:- X-ray Baggage Inspection System

Film Safe

How Safe is film Airport X-ray Scanners

- Check what National Association of Photographic Manufacturers in the USA says

- Check what Kodak says

- Check what The International Imaging Industry Association says

pls dont confuse carry on baggage machine(normal conventional x-ray machine) with checked baggage machine used in US(Explosive detection systems).Still most of the airports use conventional machines.

Radiation Levels

Typical exposure levels that can be experienced with Different types of X-ray systems and some naturally occurring sources

Medical CT (CAT Scan):Up to 1,000,000 microRem

Chest Mammography:Up to 10,000 microRem

Background Radiation Denver (5000 ft): Up to 600 microRem per day

Miami (sea level): Up to 300 microRem per day

Inside vs. outside a building: Up to 25 microRem per day

Airline Passenger Dose One hour flight: Up to 500 microRem per hour

Rapiscan Secure 1000:Less than 10 microRem per exam

Explosive Sniffing Dogs

Explosive-Sniffing Dogs normally can work for up to two hours at a time, then they must take breaks of 20 minutes. Their sensing ability decreases in repetitive duty such as routine bag inspection, their preferred use is for checking an airplane or terminal in the event of a bomb threat, or as a second-tier inspection device for a bag flagged as needing further scrut iny.

iny.

iny.

iny.Explosive Trace Detection(ETD) Machines

Watch Video Demo

Major companies

in this field

Morphosmiths detection

Thermo scientific

Automated X-ray Machines

Automated X-ray systems are used for the first level of baggage screening. While not as accurate as EDS machines, they are much faster and much less costly. Typically, they operate at a rate of 1,200 to 1,800 bags/hour, faster than explosive detection systems (EDS). Bags flagged by the automated system as “questionable” are sent to operator station, where a human operator reviews the image on a screen. Those bags not cleared by this second look are routed to an EDS machine. Automated X-ray machine is not sufficient by itself. But it pe rmits the slow and expensive EDS machines to be used only for exceptional bags.

rmits the slow and expensive EDS machines to be used only for exceptional bags.

rmits the slow and expensive EDS machines to be used only for exceptional bags.

rmits the slow and expensive EDS machines to be used only for exceptional bags.EDS Machines

EDS (explosive detection system) refers to machines that use computerized tomography (CT) technology similar to that used for CT scans in hospitals. By taking hundreds of X-ray pictures of a suitcase from different angles, the device can create three dimensional views of what is inside, including some indication of the relative density

of objects.A trained operator can then spot items likely to be explosives. EDS systems processing rate is a slow .

of objects.A trained operator can then spot items likely to be explosives. EDS systems processing rate is a slow .

Subscribe to:

Posts (Atom)